Mechanical Ventilation & Air Conditioning System

Thidaco is the leading designer , maker and supplier of complete systems for HVAC system in the Office buildings, Hotels, Factories…

Thidaco is the leading designer , maker and supplier of complete systems for HVAC system in the Office buildings, Hotels, Factories…

1. Categories of the Heating, Ventilation and Air Conditioning (HVAC) system:

1. Categories of the Heating, Ventilation and Air Conditioning (HVAC) system:

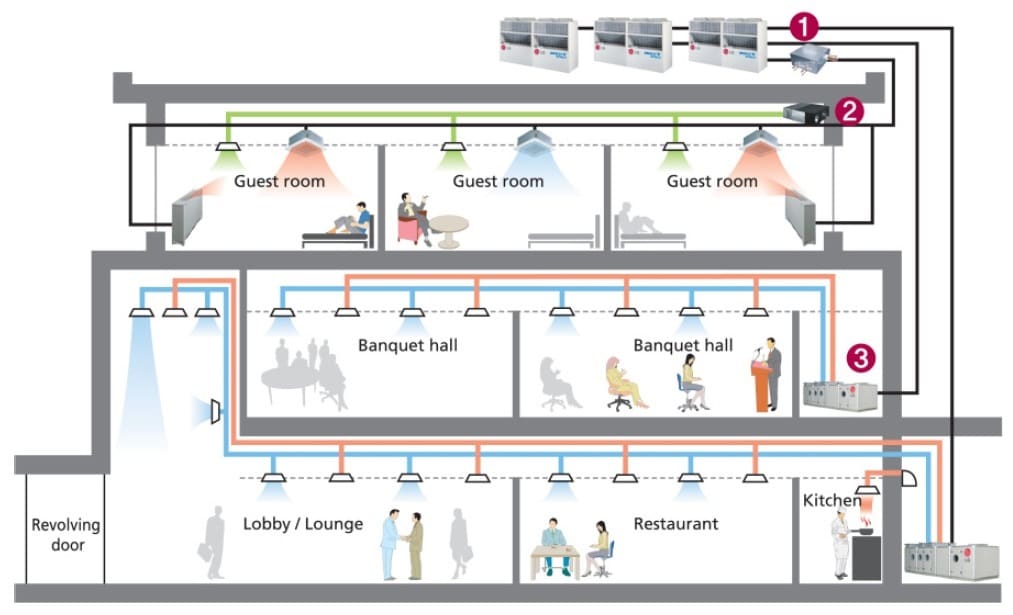

- The HVAC system ( the Air conditioner central system such as Water Chiller, VRV/VRF, air conditioner Multi, Cassete…)

- The staircase pressurization systems

- The cleanroom systems from class 100.000 to class 100

- The medical gas systems in the hospitals and pharmaceuticals

- The anti-noise and vibration systems.

2. Green Product Category: Mechanical Systems/HVAC

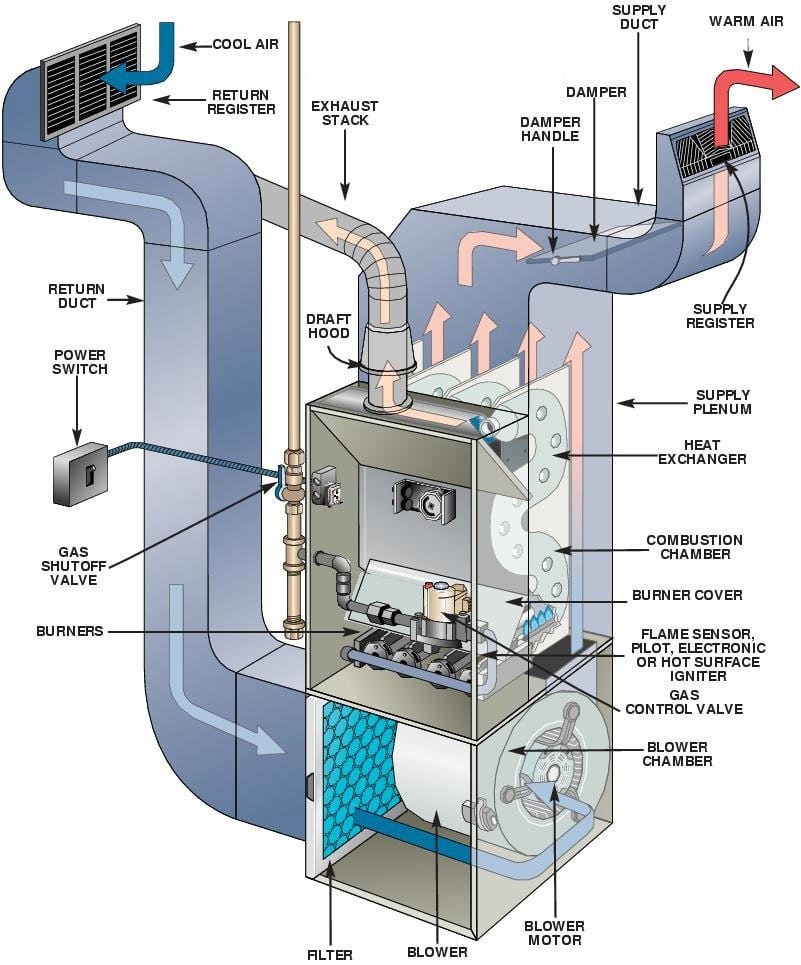

Heating, ventilation, and air-conditioning (HVAC) comprise the “engine” that drives the comfort systems in most structures. They directly consume the largest portion of energy in buildings—which makes them critically important from an environmental standpoint. Additionally, good indoor air quality, to a significant extent, depends on the ventilation they provide, while a problematic mechanical system can create and distribute indoor pollutants.

The first place to look to minimize the impact of a mechanical system isn’t the equipment, however; it’s the building’s design and construction. Careful, integrated design and optimal levels of insulation can minimize the need for supplemental heating, ventilation, or air conditioning. In situations where a central mechanical system is still necessary, an efficient building envelope can reduce the size of that system. A high-performance domestic water heater is fully capable of supplying heat to a very well-insulated house in most U.S. climates.

Building design and HVAC system strategies

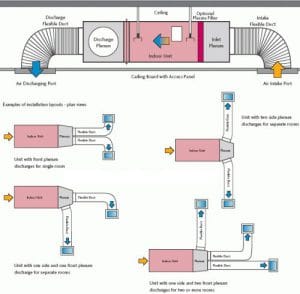

Designing a building well can also greatly reduce distribution requirements and offer tremendous potential savings in both first cost and operating costs. Houses with very well-insulated walls and high-performance windows, for example, may no longer require heat distribution at the exterior walls to provide comfort. Short duct runs to the closest point in each room save a great deal of money and space, and reduce the potential for wasteful air leakage from the duct system (which should be sealed with duct mastic, not duct tape, at all joints).

After reducing the loads that a mechanical system must meet, it’s important to size the system carefully to meet the remaining loads. An oversized system wastes money and materials initially and then operates wastefully, because heating and cooling equipment is at its most efficient when operating at full capacity.

Mechanical equipment should be as efficient as possible, durable, and installed for ease of regular maintenance. As is common practice with heating and cooling, fresh air should be provided to each occupied space and distributed to avoid pockets of trapped, stale air. To avoid the risk of backdrafting toxic flue gases such as carbon monoxide into a home, only sealed-combustion equipment should be used in houses.

Optimizing temperature and efficiency

Many air-conditioning systems still rely on HCFC refrigerants, which destroy the ozone layer if allowed to escape. These are being phased out in favor of non-ozone-depleting alternatives. The system efficiency, potential for refrigerant leakage, and ozone-depletion potential of the refrigerant should all be considered when choosing an air-conditioning system.

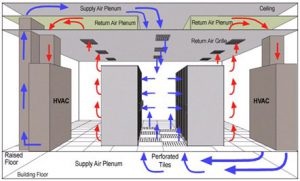

Good controls are also important. They should have setback options to adjust temperature and fresh air set-points calibrated for occupancy levels and time of day. They also should be easy to understand and use. “Smart” microprocessor-driven controllers with occupancy-detecting sensors can “learn” the activity of a household over time, activating mechanical equipment appropriately.

A mechanical system also requires careful commissioning to ensure optimal operation. During commissioning, mechanical equipment is checked for proper operation, distribution systems are balanced, and controls are all checked. All too often, careless mistakes in installation and setup result in poor system performance. Without a commissioning process, these mistakes might not be caught for years. Commissioning is important in both commercial buildings and homes. Clear, thorough documentation is critical to ensure proper ongoing maintenance and operation of systems of any size.

Combustion devices

Biomass for woodstoves, pellet stoves, wood-chip boilers, and other combustion devices is renewable as long as production of that biomass is sustainable—that is, as long as harvesting doesn’t outpace regeneration or stress the ecosystems. Some of these heating systems can generate significant amounts of air pollution, however, so appropriate pollution controls such as catalytic converters or secondary burn chambers should always be incorporated.